Common Problems Process Control System Integrators Solve In Industrial Plants

Shifts in performance often come from small issues hidden deep within automation systems. Industrial plants rely on equipment, software, and sensors working together, and even the slightest disruption can slow throughput or interrupt safety routines. Process control system integrators help uncover these problems and restore balance, ensuring plants run with steady, predictable efficiency.

Control Loop Issues That Disrupt Stable Plant Operations

A control loop must react smoothly to feedback, but drift, tuning errors, or fluctuating signals can cause overshooting, oscillation, or sluggish system responses. Control integrators study these loops to find out why a valve responds too quickly, why a pump cycles too often, or why temperature readings spike without warning. These irregularities often stem from environmental factors, mechanical wear, or poorly tuned controllers.

Once the cause is identified, adjustments are made to bring the loop back into alignment. Integrator in control system work often involves retuning PID parameters, correcting feedback paths, or replacing worn actuators to restore stability. These improvements reduce wasted energy, improve reliability, and help operators maintain consistent operation across the entire process.

How Outdated PLC Programs Create Recurring System Faults

Older PLC logic may lack proper error handling, causing repetitive faults that disrupt workflows. Legacy code frequently includes workarounds that no longer support updated plant equipment. Control system integration specialists examine these routines to identify missing conditions, obsolete instructions, or communication gaps that trigger alarm cycles. A refreshed program creates more predictable outcomes. Process control system integrators rewrite sequences, add safeguards, and reorganize logic to improve clarity and prevent freeze-ups. Updating old PLCs often brings immediate improvements by reducing downtime and ensuring newer hardware and software work seamlessly with the rest of the plant.

Sensor Inaccuracies That Throw Off Critical Readings

Sensors drifting out of calibration send misleading data to controllers. A temperature probe that reads slightly high or a pressure transducer reacting slowly can distort the entire control loop. Control integrators trace these faults to environmental exposure, wiring degradation, aging hardware, or contamination on sensing elements.

Correcting the issue begins with verifying sensor placement and calibrating each device to match real-world conditions. Process control system integrators sometimes replace outdated sensors with more reliable options that withstand harsh plant environments. Accurate data allows systems to adjust properly, reducing risk and improving overall product quality.

Why Poor Network Design Slows Down Real-time Communication

Industrial networks must carry rapid, uninterrupted data between controllers, HMIs, drives, and field devices. Congested networks, improper routing, or outdated switches can delay communication, causing commands to lag. Control system integration professionals evaluate message paths, bandwidth loads, and protocol compatibility to locate weak points.

Optimizing the network often involves segmenting traffic, replacing aging components, or adjusting communication priorities. Integrator in control system projects frequently include redesigning the layout to ensure real-time signals take the most efficient path. With improved communication, systems respond more quickly and operators gain more reliable visibility into plant operations.

Alarm Overloads That Hinder Operator Decision-making

Alarm floods overwhelm operators with information, making it hard to separate routine alerts from critical warnings. Excessive alarms often result from poorly configured thresholds, duplicated messages, or old logic that no longer matches plant conditions. Control integrators review alarm histories to pinpoint patterns that indicate an overloaded system.

Reducing alarm noise begins with reorganizing priorities and eliminating unnecessary triggers. Process control system integrators create tiered alarm structures that highlight urgent conditions while suppressing repetitive low-risk alerts. With a cleaner alarm strategy, operators make faster, more confident decisions under pressure.

How Inconsistent Data Flow Affects Production Quality

Uneven or delayed data disrupts automated adjustments throughout the system. For example, inconsistent flow meter readings might cause uneven batching, or intermittent temperature data may affect heating cycles. Control integrators look for gaps in database communication, protocol mismatches, or overloaded controllers that struggle to process incoming values.

Stabilizing data flow often requires balancing distributed control loads or improving how information is transferred between systems. Control system integration ensures that historical and real-time data remain synchronized, providing operators and automated routines with dependable information. Consistent data strengthens quality control by keeping processes aligned.

Equipment Coordination Gaps That Stall Automation Sequences

Automation relies on multiple devices working in sync, but timing mismatches or missing confirmation signals can stall sequences. This often appears in conveyor systems, robotic stations, or multi-step mixers where each piece of equipment must wait for the one before it. Integrator in control system analysis identifies which device fails to send or receive handshakes correctly.

Fixing coordination issues sometimes requires rewriting sequence logic or improving how devices communicate over the network. Process control system integrators work to create seamless transitions from one step to the next, reducing downtime and preventing jams that interrupt plant flow.

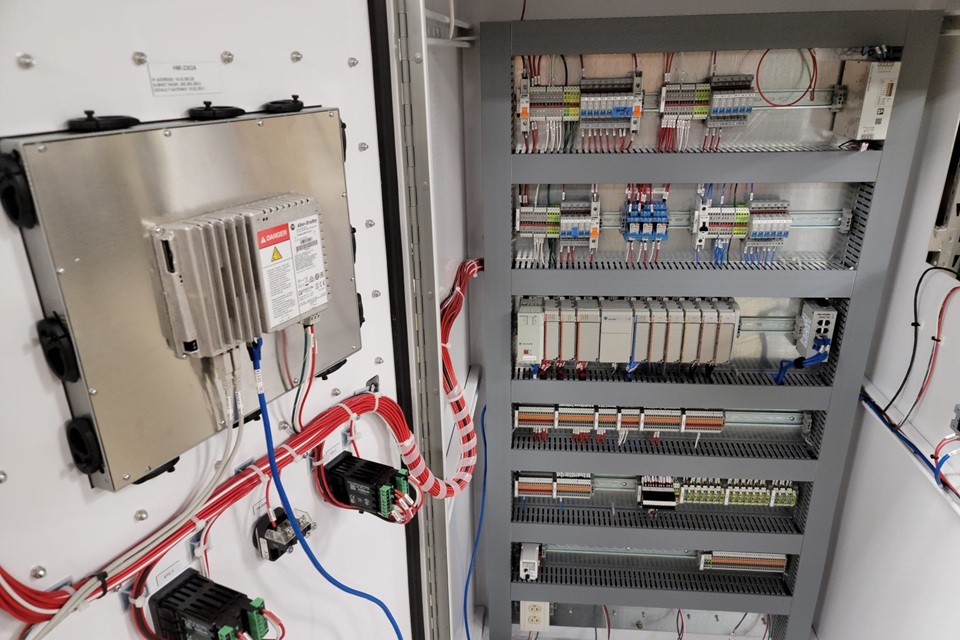

Why Mismatched Hardware Reduces Overall System Reliability

Plants often upgrade equipment gradually, leaving old and new components working together in ways they were not designed for. Different communication protocols, voltage standards, or update rates can introduce unpredictable behavior. Control integrators test compatibility between PLCs, drives, I/O modules, and sensors to find mismatches.

Standardizing components or adding conversion hardware helps align the system. Control system integration aims to build a cohesive environment where each device communicates properly and performs at its intended speed. This approach boosts reliability and extends the life of both new and legacy equipment.

Industrial facilities benefit greatly from specialists who resolve these hidden issues before they disrupt operations. RL Consulting supports plants by diagnosing control challenges, optimizing integration, and delivering long-term solutions that strengthen system reliability.